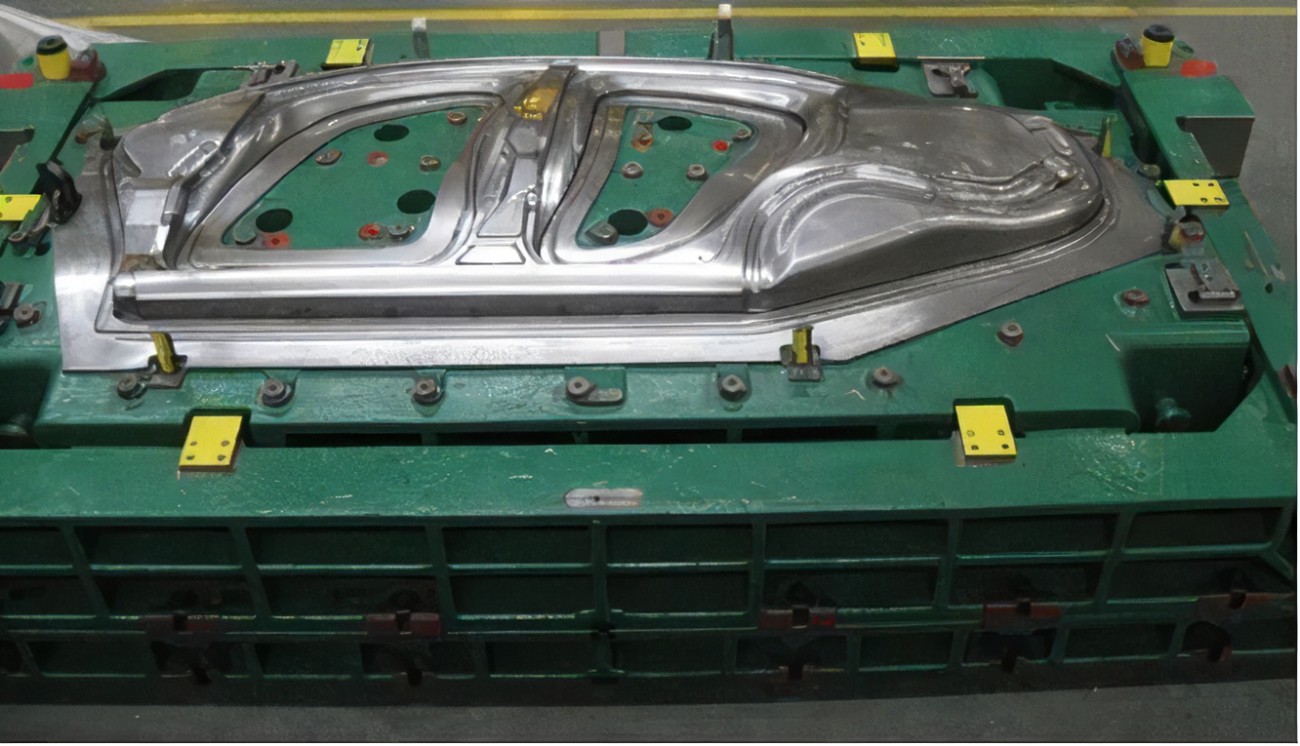

During the use of metal stamping molds, natural wear of mold parts, unreasonable mold manufacturing process, improper installation or use of molds on machine tools, equipment failure, etc. may cause the main components of the mold to lose their original performance and precision, resulting in the deterioration of the mold's technical status, affecting normal production and efficiency as well as product quality.

Here are some suggestions on daily maintenance of metal stamping dies, I hope it will be helpful to you.

Clean the mold surface: The mold surface should be cleaned regularly before and after use. Use a soft cloth or brush to remove dust, oil and other impurities on the mold surface. You can use a special cleaner to clean the mold, but be careful to choose a cleaner that will not corrode the mold surface.

Lubricate mold parts: The parts of the mold need to be well lubricated to reduce friction and wear. Before using the mold, you can use a suitable lubricant to apply to the sliding surface and contact surface of the mold. The choice of lubricant should be determined according to the mold material and working environment. Avoid using lubricants containing acid and alkali components to avoid corrosion to the mold.

Avoid overusing the mold: The service life of the mold is related to the frequency of use and the conditions of use. Excessive use of the mold will cause fatigue and wear, reducing the life of the mold. Therefore, when using the mold, the production plan should be arranged reasonably according to the needs to avoid excessive use of the mold.

Regularly check the condition of the mold: Regularly check the condition of the mold, including wear, cracks and deformation on the mold surface. If the mold is found to be damaged or abnormal, it should be repaired or replaced in time. Regular inspections can also help find problems during the use of the mold and take timely measures to adjust and improve it.

When storing the mold, pay attention to moisture and rust prevention: When the mold is not in use temporarily, it should be properly stored. The mold should be placed in a dry and ventilated place to avoid moisture and heat. A layer of rust inhibitor can be applied on the surface of the mold to prevent the mold from rusting.

Keep good mold maintenance records: Establish mold maintenance records to record the use, maintenance and repair of the mold, etc. This can help understand the service life and maintenance of the mold, and take timely measures to adjust and improve it.

In short, the daily maintenance of metal stamping dies is essential to ensure the service life of the dies and production quality. Through regular cleaning, lubrication, inspection and storage, the service life of the dies can be extended, and production efficiency and product quality can be improved. At the same time, establishing a mold maintenance record can help understand the use and maintenance of the dies, and take timely measures to adjust and improve them.

Xuanmin provides the best aluminum extrusion services to get the desired results. Contact us and let us turn your project into reality. You can also upload your design files to our digital quotation platform to get instant quotes and a transparent ordering process.