The Impact of Progressive Die Stamping

Die Stamping

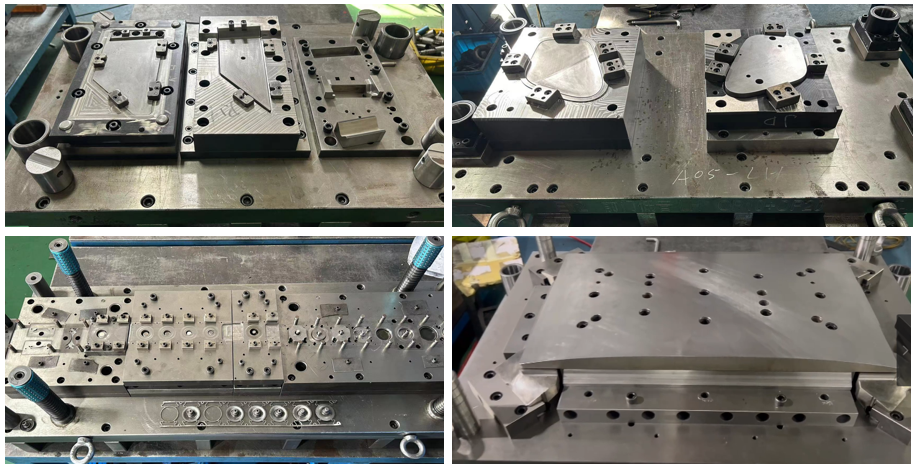

Shaping the future of metal components, Progressive stamping die emerges as a cornerstone of efficiency and precision within the metal

fabrication sector. This cutting-edge manufacturing technique is more than just metal shaping;

it’s a transformative process that guarantees the creation of high-quality parts at exceptional speed and accuracy. Serving a wide range of

industries—from automotive to consumer electronics—it underscores its versatility and essential role!

What sets this method apart is its capacity to produce intricate, three-dimensional parts in substantial quantities, from thousands to millions,

all while maintaining impeccable precision and quality. The combination of rapid production, efficiency, and cost-effectiveness makes advanced die stamping the go-to choice for manufacturers striving for excellence in metal component production. This process converts metal coils into complex parts through a sequence of stamping operations, ensuring minimal waste and optimal efficiency.

Additionally, the in-house design and crafting of advanced tooling by skilled professionals allow for the customization of parts to meet specific requirements, whether it’s sophisticated electronic enclosures or precision-engineered brackets. This tailored approach not only fulfills but frequently exceeds client expectations regarding quality and performance.

The advantages of choosing Progressive die stamping are vast. It significantly minimizes scrap metal, speeds up production timelines, and achieves tighter tolerances, ensuring a high level of repeatability. This efficiency translates into lower costs per part, a crucial aspect for maintaining competitive advantages and sustainability within the market.

In the arena of custom metal stamping, Innovative die solution stands as a beacon of quality and innovation.

With over 20 years in the industry, the company has refined its expertise and resources to deliver unmatched precision and reliability.

By implementing rigorous quality control processes and adhering to ISO 9001 standards, it guarantees the highest quality across all projects.

This dedication to excellence, coupled with an in-depth understanding of the progressive die stamping process, positions Innovative Die Solutions as a frontrunner in the field. For businesses seeking to enhance their metal component production, partnering with a trusted leader like Innovative Die Solutions is the path to success.