Understanding the Mold Manufacturing Process

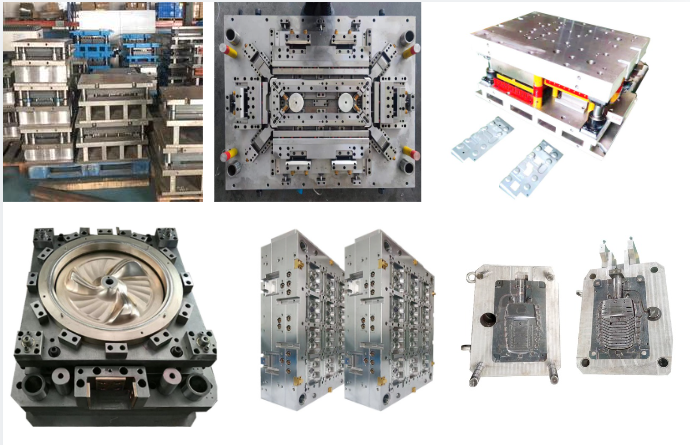

At Xuanmin Tech , we pride ourselves on our comprehensive mold manufacturing process.

Each step is meticulously designed to ensure the highest quality and precision in the final product.

Here’s an overview of how we create exceptional molds for our clients.

Step 1: Consultation and Design

The process begins with an in-depth consultation. We work closely with our clients to understand their specific requirements, including design specifications, material preferences, and production goals. Our design team then utilizes advanced CAD software to create detailed 3D models of the molds.

Step 2: Prototyping

Once the design is finalized, we move on to prototyping. This critical step allows us to create a physical representation of the mold. Prototypes help identify any potential issues in the design and provide an opportunity for our clients to give feedback before moving to full production.

Step 3: Material Selection

Choosing the right material is essential for mold durability and performance. We offer a variety of materials, including:

- Steel: Ideal for high-volume production and durability.

- Aluminum: Lightweight and cost-effective for lower production runs.

Specialty Alloys: Tailored for specific applications requiring unique properties.

Step 4: Precision Machining

Using state-of-the-art CNC machining and EDM (Electrical Discharge Machining), we manufacture the molds with outstanding precision. This technology allows us to achieve tight tolerances and intricate details, ensuring that the molds meet the precise specifications.

Step 5: Quality Control

Quality assurance is integrated throughout the manufacturing process. Each mold undergoes rigorous testing and inspection at various stages to ensure it meets our high standards and complies with industry regulations.

Step 6: Finishing Touches

After machining, we apply finishing processes such as polishing, coating, or texturing, depending on the requirements of the mold and the final product. These enhancements improve both the functionality and aesthetics of the mold.

Step 7: Final Inspection and Delivery

Before delivery, each mold undergoes a final inspection to ensure it meets all specifications and quality standards. Once approved, we package and ship the molds to our clients, ensuring they arrive safely and on time.

The mold manufacturing process at xuanmin mold prodution is designed to provide our clients with high-quality, reliable molds tailored to their specific needs. If you're ready to start your next project, contact us today to learn more about our services!